Revista Portuguesa de Estomatologia, Medicina Dentária e Cirurgia Maxilofacial

Revista Portuguesa de Estomatologia Medicina Dentária e Cirurgia Maxilofacial | 2021 | 62 (4) | 201-208

Original research

Effect of number of implants, distal implant inclination, and angled abutment on stresses in fixed complete dentures: a nonlinear finite element analysis

Efeito de número de implantes, inclinação do implante distal e angulação de pilares nas tensões em próteses totais fixas implantossuportadas: análise de elementos finitos não lineares

a Pontifícia Universidade Católica do Rio Grande do Sul, Porto Alegre, RS, Brasil

b Universidade de Caxias do Sul, Caxias do Sul, Brasil

Tomás Geremia - tgeremia@pucrs.br

Article Info

Rev Port Estomatol Med Dent Cir Maxilofac

Volume - 62

Issue - 4

Original research

Pages - 201-208

Go to Volume

Article History

Received on 21/02/2021

Accepted on 18/08/2021

Available Online on 23/11/2021

Keywords

Original Research

�

Effect of number of implants, distal implant inclination, and angled abutment on stresses in fixed complete dentures: a nonlinear finite element analysis

Efeito de n�mero de implantes, inclina��o do implante distal e angula��o de pilares nas tens�es em pr�teses totais fixas implantossuportadas: an�lise de elementos finitos n�o lineares

�

Tom�s Geremia1,* 0000-0002-8856-2627

Leonardo Hoffmann de Barcellos1 0000-0003-4648-1404

Leandro Luis Corso2 0000-0001-9962-9578

Eduardo Aydos Villarinho1 0000-0001-6742-9643

Rosemary Sadami Arai Shinkai1 0000-0002-4107-5661

1 Pontif�cia Universidade Cat�lica do Rio Grande do Sul, Porto Alegre, RS, Brasil

2 Universidade de Caxias do Sul, Caxias do Sul, Brasil

�

�

Article history:

Received 22 February 2021

Accepted 18 August 2021

Available online 23 November 2021

�

Abstract

Objectives: This nonlinear three-dimensional finite element analysis (FEA) study evaluated the effect of the number of implants, distal implant inclination, and use of angled abutments on stress magnitude and distribution in cortical bone (CB), abutment screw (AS), and prosthetic screw (PS) of implant-supported fixed complete dentures.

Methods: Nonlinear 3D FEA models of mandibular fixed complete dentures were created with five, four, or three parallel straight implants (5S, 4S, 3S) and with tilted distal implants (5T, 4T, 3T). In addition, the 5T model was tested using angled abutments over the tilted distal implants to re-align the implant inclination. A 100-N axial load was applied over the first molar region (cantilever) to analyze the von Mises stresses in selected points (CB, AS, and PS).

Results: The implant adjacent to the load showed the highest stresses in CB, AS, and PS. The model with three implants showed higher stresses than the ones with four and five implants. Peak stresses in the AS increased 40% from five to four implants and 100% from five to three implants. Tilting the distal implants increased stresses in CB. Peak stress in the PS increased 150% from 5S to 5T models and 100% from 4S to 4T models. Angled abutments generated lower stresses on CB and AS but higher stresses on PS.

Conclusions: The results suggest that stresses in the cortical bone, abutment screw, and prosthetic screw increase when tilting the posterior implants and reducing the number of implants. The use of angled abutments decreased stresses at the bone-implant interface and in abutment screws but increased stresses on prosthetic screws.

Keywords: Angled abutment, Biomechanics, Finite element analysis, Full-arch denture, Implant inclination.

�

Resumo

Objetivos: Este estudo com an�lise de elementos finitos (EF) 3D n�o lineares avaliou a influ�ncia do n�mero de implantes, da inclina��o de implantes distais e do uso de pilares angulados sobre as tens�es em osso peri-implantar cortical (CB), parafuso do pilar prot�tico (AB) e parafuso prot�tico (PS) em pr�teses totais fixas implantossuportadas (IFCD).

M�todos: Modelos de EF-3D n�o lineares de IFCD mandibulares foram criados com cinco, quatro e tr�s implantes paralelos entre si (5R, 4R, 3R) e com o implante distal inclinado (5I, 4I, 3I). Adicionalmente, no modelo 5I foi testado o uso de pilares angulados, compensando a angula��o do implante. Uma for�a axial de 100 N foi aplicada sobre o primeiro molar (extremo livre) para avaliar as tens�es em pontos selecionados (CB, AS, PS).

Resultados: O implante adjacente � carga mostrou maiores tens�es em CB, AS e PS. O modelo com tr�s implantes apresentou maiores tens�es que com quatro ou cinco. Quanto ao AS, o pico tensional aumentou 40% de cinco para quatro implantes e 100% de cinco para tr�s implantes. A inclina��o distal do implante posterior aumentou as tens�es em CB. Quanto ao PS, o pico tensional aumentou 150% do modelo 5R para o 5I e 100% do modelo 4R para o 4I. O pilar angulado diminuiu as tens�es em CB e AS, mas aumentou em PS.

Conclus�es: Os resultados sugerem que as tens�es em CB, AS e PS aumentam quando h� inclina��o do implante distal e diminui��o do n�mero de implantes. O uso de pilares angulados diminui as tens�es em CB e AS, mas aumentou as tens�es em PS.

Palavras-chave: Pilar angulado, Biomec�nica, An�lise de elemento finito, Pr�tese total fixa, Implante inclinado.

�

Introduction

For implant-supported fixed complete dentures (IFCD), implants are often installed between the mandibular mental foramina or the maxillary sinuses, with the most posterior implants located at the premolar region. To replace dentition and provide occlusal support up to the first molars, these full-arch prostheses have posterior free-ends, which function as a lever under occlusal loads, yielding stresses, torques, and bending moments. 1 - 4 It is common sense to reduce the distal cantilever extension as much as possible. However, its cut-off size or maximum length are still unknown as other factors, such as distal implant inclination, number and distribution of implants along the arch, prosthetic materials, and framework design, may also be associated with potential occlusal overload. 5 -

11Some alternative procedures for planning IFCD aim at modifying the biomechanical design to reduce strains and stresses in the prosthesis-implant-bone system. Studies reported that inclining posterior implants distally may allow better anteroposterior distribution in the arch, avoiding anatomical structures and bone grafting, as well as reducing the cantilever length. 6, 8, 12 Other studies with tilted distal implants

reduced the number of implants to simplify the technique, decrease costs, and ease cleaning.13, 14 Additionally, using an angled abutment over a tilted implant could compensate for the implant inclination and align the prosthesis insertion axis with adjacent elements to facilitate the clinical procedures and laboratory fabrication.15 However, the direct biomechanical effect of these variables on stresses generated at the peri-implant bone, implant, and prosthetic components cannot be measured clinically.8, 16, 17

The finite element method is a computational analysis to simulate complex models that generates strain/stress in selected areas of interest where experimental or clinical methods are not feasible (e.g., implant-bone interface and internal screws).

The computational simulation requires detailed bone geometry and modeling of implant and components, material properties (modulus of elasticity and Poisson�s coefficient), and bone/implant interface, which are quite variable in the literature. 18 - 21

Despite its limitations, the finite element method can control each variable in the simulation for a particular effect and thus help explain some empirical events to justify clinical protocols.

This study evaluated the effect of the number of implants, the distal tilting of posterior implants, and the use of angled abutments on stress magnitude and distribution in the peri-implant cortical bone, abutment screw, and prosthetic screw of mandibular IFCDs, using nonlinear finite element analysis (FEA).

Material and methods

A three-dimensional (3D) computer prototype of a human mandible was used to generate an epoxy resin model. Five external hexagon implants with a regular platform of 3.75 x 11.50 mm (OSS 311, Biomet 3i, USA) were installed axially, parallel and equidistant to each other, between the mental foramina. The implants received multi-unit screw-retained abutments (BRUA43, Biomet 3i, Brazil) with a 3-mm collar. A

full-arch IFCD was waxed-up, duplicated in acrylic resin, and reduced by 2 mm in all directions, except for the adjustment of the cylinders onto the abutments, to simulate the metallic framework. Three metal spheres were fixed to the surface to serve as reference points during the image acquisition by laser scanning.

The 3D images were superimposed, and small imperfections were corrected manually using the software Geomagic 7.0 (Raindrop, Research Triangle Park, USA). The solids of implant and prosthetic components were generated using measurements recorded with a digital caliper and an optical microscope.

The system composed of mandible, implants, abutments, and prosthesis was assembled. The prosthetic and infrastructure solids were superimposed using the cylinders as a reference point.

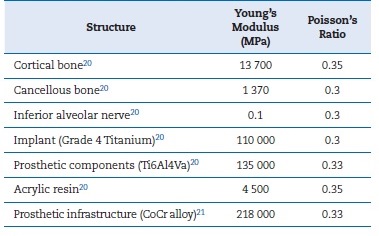

The solids set was exported to the program Rhynoceros 3D� version 3.0 (McNell & Associates, Inc., USA) to generate a continuous model for prosthesis, infrastructure, components, implants, and mandible. The FEA models were obtained by importing the meshed models to the software ANSYS 13.0 (Ansys, Houston, USA). All models were considered homogeneous, isotropic, and nonlinear. A friction coefficient of μ = 0.5 between prosthetic components was adopted.20 Table 1 shows the Young�s modulus of elasticity and Poisson�s ratio coefficient values of the materials and tissues used.22, 23 In the bone/implant interface, a perfect contact between bone and implants (100% osseointegration) was assumed.

�

Table 1. Physical properties of the simulated structures according to the literature.20 21

�

Two virtual situations were simulated:

- Straight model: All implants were axially placed and parallel to each other;

- Tilted model: The two posterior implants were inclined by 27 degrees distally, using their platform as the rotation fulcrum.

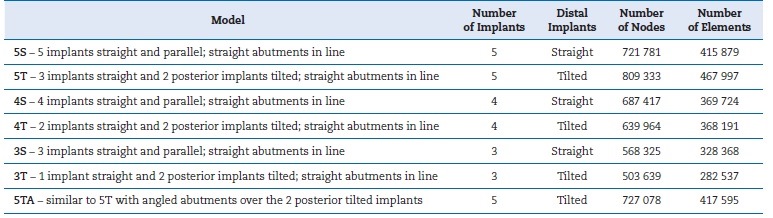

The straight and tilted models were tested by changing the number of implants (three, four, or five). In addition, the tilted model with five implants was simulated with angled abutments (27 degrees) over the two posterior tilted implants to �correct� their inclination. Thus, a total of seven models were tested, models and their abbreviations are fully described in Table 2.

�

Table 2. Nonlinear FEA models with the respective number of nodes and elements.

�

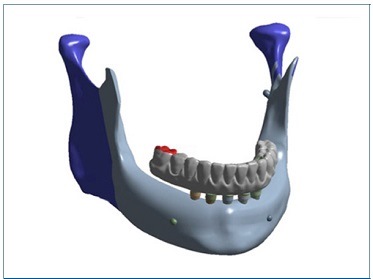

The bilateral insertions of the masseter muscle and the temporomandibular joints served as a fixed-point constraint set to no movement in the x, y, and z axes. A static axial load of 100 N was simulated onto the occlusal surface of the right first molar, which represented the cantilever extension (Figure 1).7

�

Figure 1. Three-dimensional model for simulation of the axial force applied on the first right molar (shown in red). The constraints were set as fixed points representing the masseter muscle and temporomandibular joint insertions, bilaterally (shown in blue).

�

The virtual load simulations on the models were analyzed to measure and compare the stress magnitude and distribution through the von Mises analysis system (maximum equivalent stress - EQV-MPa) for the cortical bone (CB), prosthetic abutment screw (AS), and prosthetic screw (PS).

Results

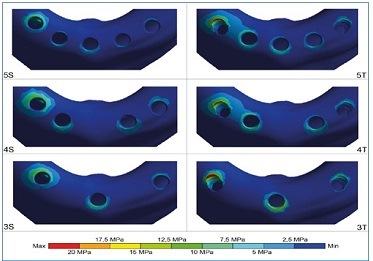

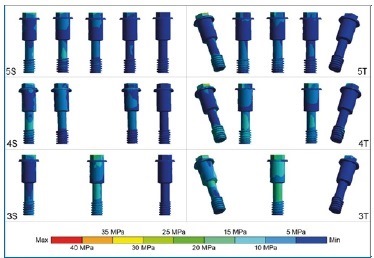

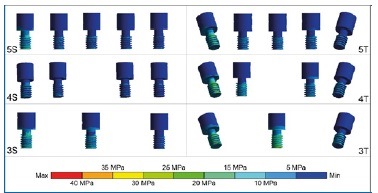

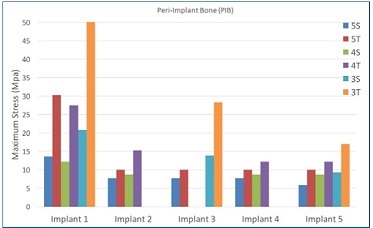

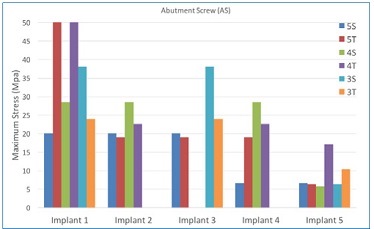

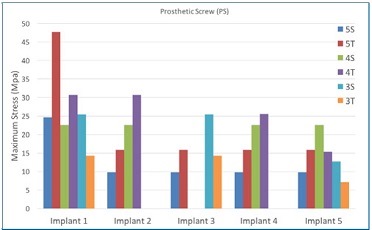

The implant adjacent to the loading area showed the highest stress magnitudes at CB, AS, and PS for all models. Figures 2, 3, and 4 show the stress distribution and maximum peak values for the AS and PS in the models with straight abutments. Figures 5, 6, and 7 display the maximum stress peaks for each region of interest (AS and PS), per implant.

�

Figure 2. Stress distribution on the cortical bone under axial load at the prosthesis cantilever (right side). In all models, maximum peak stress occurred in the distal portion of the implant adjacent to the load; the anterior implant(s) had stress concentration in the anterior region. The greatest stresses were found in model 3T. The model 5S showed the most uniform distribution and the lowest stress peaks.

�

Figure 3. Stress distribution on the abutment screws under axial load at the prosthesis cantilever (right side). The screws of tilted posterior implants adjacent to the load in the 4T and 5T models had higher stress peaks near the female thread areas. The 3T model displayed a larger area of stress, with a higher magnitude, on its �body.� Among straight models, the 3S model had greater stress on all abutment screws.

�

Figure 4. Stress distribution on the prosthetic screws under axial load at the prosthesis cantilever (right side). The screws of tilted posterior implants adjacent to the load had the largest stresses, regardless of the number of implants. The anterior screw showed more stress in models with three implants than in those with four and five implants, especially in model 3T.

�

Figure 5. Maximum stress peaks on the cortical bone, in MPa, for each implant in the arch. In models 4S and 4T, implant #3 was not used; in models 3S and 3T, implants #2 and #4 were not used.

�

Figure 6. Maximum stress peaks on the prosthetic screw, in MPa, for each implant in the arch. In implant #1, the increase in stress peak was inversely proportional to the number of implants for straight models (5S, 4S, and 3S). Implant #1 in the 5T and 4T models showed the highest stress peaks.

�

Figure 7. Maximum stress peaks on the prosthetic screw, in MPa, for each implant in the arch. In general, the tilted models displayed higher stress peaks in all implants than straight models for the same number of implants.

�

The implant adjacent to the loading area showed the highest stress magnitude at CB, AS, and PS for all models. Peak stress in the AS increased 40% from five to four implants and 100% from five to three implants. The prosthesis supported by three implants showed higher stress values than the models with four and five implants.

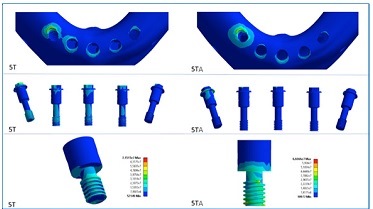

Tilting the implants without distalizing the implant platforms increased von Mises stresses in CB. Peak stress in the PS increased 150% from 5S to 5T models and 100% from 4S to 4T models. The use of angled abutments on the distal implants generated lower stresses on the CB and AS but higher stresses in the PS (Figure 8).

�

Figure 8. Comparison of stress distribution on the cortical bone, abutment screws, and prosthetic screws between the five-implant models with tilted posterior implants and straight or angled abutments (models 5T - straight abutments; 5TA -angled abutments). Angled abutments decreased the stress in cortical bone and abutment screws but increased stress in prosthetic screws.

Discussion

This FEA study showed that the stress magnitude and distribution were affected by the number of implants, the inclination of distal implants, and the use of angled abutments in mandibular IFCDs. In general, the stresses in the CB, AS, and PS increased when inclining the distal implants and using three implants. On the other hand, the use of angled abutments to �correct� the distal implant inclination showed mixed effects, as they decreased the stresses and strains at the bone-implant interface and in the AS but increased the stresses in the PS.

Regarding the CB, the maximum stress peaks did not vary between straight or tilted distal implants in models with either five or four implants. Although some clinical studies found no association between bone loss and distal implant angulation or cantilever length,24, 27 the inclination of posterior implants was shown to reduce peri-implant bone stresses in laboratory and FEA studies.16, 17, 28 However, in the three-implant model, the maximum stress peaks in CB were higher than in models with four or five implants, regardless of distal implant inclination.

Moreover, the stress in ASs increased when reducing the number of implants from five to four and from five to three implants. These findings suggest a biomechanical loss when using three implants to support and retain an IFCD because the formation of a triangular polygon support is less effective than a square one to distribute the occlusal loads in the bone-implant-prosthesis system across the arch.

In addition, the use of tilted distal implants in the three-implant model substantially increased the maximum stress in the most anterior implant. The tensile forces in the anterior region result from a rocking movement generated by the load application at the cantilever, where the posterior implants act as a rotation fulcrum of compressive forces. In a clinical study using extensometers, Duyck et al. 2 observed this biomechanical phenomenon and called it a �hinging effect.�

Sometimes the tilting of distal implants causes a divergence of the prosthesis insertion axis, making laboratory preparation difficult or impossible. One way to overcome this problem is using angled abutments to reestablish the prosthesis insertion axis closer to the ideal clinical situation or where the PSs would emerge in esthetic zones.14, 15 However, the stresses� magnitudes and distribution are affected by this alternative design due to different transmission of occlusal loads to the entire system. The tilted model with distal implants �corrected� by angled abutments had reduced maximum stress in CB compared to the straight model. When comparing the use of angled and straight abutments in the tilted model with five implants, in the models with angled abutments, the region near the �female� portion of the AS wall closest to the loading site showed higher stresses. In models with straight abutments, there were increased stresses close to the region where this screw sits on the abutment.

Regarding the PSs, the highest stress concentration occurred in the PS close to the loading site for all models. The distal PSs on straight abutments had lower stress than those on angled abutments. Thus, the screws of straight abutments placed over inclined implants in the same axis may have less risk of loosening or fracture. A systematic review of clinical studies showed that screw and abutment loosening were frequent when using angled abutments, as well as more marginal bone loss compared to straight abutments after one year of function.29

The inclination of distal implants aims at reducing the length of the prosthetic cantilever with a simultaneous inclination and distalization of the implant platform. In IFCD, the fulcrum point for implant rotation varies according to the anatomical position of the mental foramina, bilaterally. The more �apical� the foramina are, the more �apical� the fulcrum point of the implant�s rotation may be. Clinically, posterior implant tilting is performed simultaneously to the distalization of the emergence of the implant platform.12 - 14 In this study, the posterior implants were tilted by 27 degrees distally, with the implant platform being the fulcrum point for rotation, which did not result in a displacement of the implant body. Implant distalization was not incorporated in the simulated models to avoid a new joint variable and a more complex stress interpretation. The fact that there was no distal movement of the implant platform (via implant tilting) may explain the greater stress in inclined implants.

For the models with four and five implants, tilting the posterior implants increased the maximum stresses in the AS by 100% and 150%, respectively. The stress in ASs of straight models increased as the number of implants decreased. The anteroposterior distribution of the three-implant model resulted in a larger resistance arm than the other models, but this may not be sufficient to decrease overall stresses. In this study, an approximation of anterior implants was not performed, which would provide better comparability between the positions of implants in the arch among the models tested.

Fazi et al.30 simulated models in which the anterior implants were redistributed and analyzed the effects on cortical and cancellous bone. However, in both cases (with and without anterior implant approximation), these models had only four implants parallel to one another. A configuration with implants equidistant from each other resulted in slightly lower stress magnitudes.

The literature still does not provide definitive evidence of the tolerable stress limits for each part of the bone-implant-prosthesis system without clinical harm. Accordingly, the

present study�s findings should be carefully evaluated as the degree of stress that may cause any mechanical failure (loosening or fracture of prosthetic components or implants) or biological failure (peri-implant bone resorption or osseointegration failure) is unknown. Recent systematic reviews reported no association between the number of implants used to support IFCDs and survival rates of implant and prosthesis, complications, or bone loss in studies with follow-ups ranging from 1 to 15 years.31, 33 However, most of the clinical studies included were heterogeneous and did not address the primary question of the number of implants with standardized methods, and the biological conditions, such as occlusal force and quantity and quality of bone, were not controlled. For example, an FEA study on the influence of bone quality on stress distribution in IFCD showed that the less compact bones (poor bone quality) increased the stresses in implants and prosthetic superstructure and decreased the stresses in trabecular bone.19

Ferreira et al.34 aimed to validate a numerical model that could be used to study stresses and strains created in the different components involved in oral fixed rehabilitations through FEA and static compressive load test (SCLT). Analyzing the tendencies of both models, an absolute match of their biomechanical behaviors can be observed, validating the computational model. However, such findings are more easily transposed to mechanical failures since biological tissues, such as bone tissue, are reproduced in simulation studies that are quite controversial, requiring clinical studies.

The distribution and magnitude of stresses result from a complex combination of mechanical and biological factors that interact simultaneously. The finite element method enables simulation of forces applied to selected structures, but some model simplifications are required. The present study used a nonlinear finite element method with a friction coefficient of 0.5 to improve the accuracy in simulating the relationship among implant and prosthetic components.20 In the bone/implant interface, a 100% osseointegration was adopted because the anterior mandible has high bone density,20, 22, 23

despite uneven contact between bone and implant.18 Therefore, the results of FEA studies should be interpreted with caution and cannot be directly extrapolated to the clinical practice.

Although it is impossible to completely reproduce the clinical situation, the FEA method is useful to understand the effect of isolated factors in prosthesis design. Thus, the present findings may help clinicians carefully evaluate the patient�s conditions to plan the treatment with IFCD, lowering biomechanical risks accordingly. Furthermore, it can provide subsidies for the control of variables in future clinical studies.

Conclusions

Within the limitations of this study, the findings suggest that:

� Von Mises strains/stresses in the CB, ASs, and PSs increase when tilting the posterior implants and reducing the number of implants;

� The use of angled abutments over tilted implants can reduce the stresses in CB and abutment screws, but its prosthetic screws are more stressed than in straight abutments.

�

References

1. Glantz PO, Rangert B, Svensson A, Stafford GD, Arnvidarson B, Randow K, Lind�n U, Hult�n J. On clinical loading of osseointegrated implants. A methodological and clinical study. Clin Oral Implants Res. 1993;4:99-105.

2. Duyck J, Van Oosterwyck H, Vander Sloten J, De Cooman M, Puers R, Naert I. Magnitude and distribution of occlusal forces on oral implants supporting fixed prostheses: an in vivo study. Clin Oral Implants Res . 2000;11:465-75.

3. Ogawa T, Dhaliwal S, Naert I, Mine A, Kronstrom M, Sasaki K, Duyck J. Effect of tilted and short distal implants on axial forces and bending moments in implants supporting fixed dental prostheses: an in vitro study. Int J Prosthodont. 2010;23:566-73.

4. Naconecy MM, Geremia T, Cervieri A, Teixeira ER, Shinkai RS. Effect of the number of abutments on biomechanics of Branemark prosthesis with straight and tilted distal implants. J Appl Oral Sci. 2010;18:178-85.

5. Gallucci GO, Doughtie CB, Hwang JW, Fiorellini JP, Weber HP. Five-year results of fixed implant-supported rehabilitations with distal cantilevers for the edentulous mandible. Clin Oral Implants Res . 2009;20:601-7.

6. Suedam V, Moretti Neto RT, Sousa EAC, Rubo JH. Effect of cantilever length and alloy framework on the stress distribution in peri-implant area of cantilevered implantsupported fixed partial dentures. J Appl Oral Sci . 2016;24:114-20.

7. Sheridan RA, Decker AM, Plonka AB, Wang HL. The Role of Occlusion in Implant Therapy: A Comprehensive Updated Review. Implant Dent. 2016;25:829-38.

8. Ozan O, Kurtulmus-Yilmaz S. Biomechanical comparison of different implant inclinations and cantilever lengths in All-on-4 treatment concept by three-dimensional finite element analysis. Int J Oral Maxillofac Implants. 2018;33:64-71.

9. Walter L, Greenstein G. Utility of measuring anteriorposterior spread to determine distal cantilever length off a fixed implant-supported full-arch prosthesis: A review of the literature. J Am Dent Assoc. 2020;151:790-5.

10. Chrcanovic BR, Kisch J, Larsson C. Retrospective evaluation of implant-supported full-arch fixed dental prostheses after a mean follow-up of 10 years. Clin Oral Implants Res . 2020;31:634-45.

11. Papaspyridakos P, Barizan Bordin T, Kim YJ, DeFuria C, Pagni SE, Chochlidakis K, Rolim Teixeira E, Weber HP. Implant survival rates and biologic complications with implantsupported fixed complete dental prostheses: A retrospective study with up to 12-year follow-up. Clin Oral Implants Res . 2018;29:881-93.

12. Krekmanov L, Kahn M, Rangert B, Lindstr�m H. Tilting of posterior mandibular and maxillary implants for improved prosthesis support. Int J Oral Maxillofac Implants . 2000;15:405-14.

13. Mal� P, de Ara�jo Nobre M, Lopes A, Ferro A, Botto J. The All-on-4 treatment concept for the rehabilitation of the completely edentulous mandible: A longitudinal study with 10 to 18 years of follow-up. Clin Implant Dent Relat Res. 2019;21:565-77.

14. Wentaschek S, Lehmann M, Scheller H, Weibrich G, Weibrich G, Behneke N. Polygonal area of prosthesis support with straight and tilted dental implants in edentulous maxillae. Int J Prosthodont . 2016;29:245-52.

15. Cavallaro J Jr, Greenstein G. Angled implant abutments: a practical application of available knowledge. J Am Dent Assoc . 2011;142:150-8.

16. Naini RB, Nokar S, Borghei H, Alikhasi M. Tilted or parallel implant placement in the completely edentulous mandible? A three-dimensional finite element analysis. Int J Oral Maxillofac Implants . 2011;26:776-81.

17. Kim KS, Kim YL, Bae JM, Cho HW. Biomechanical comparison of axial and tilted implants for mandibular full-arch fixed prostheses. Int J Oral Maxillofac Implants . 2011;26:976-84.

18. Sato Y, Teixeira ER, Tsuga K, Shindoi N. The effectiveness of a new algorithm on a three-dimensional finite element model construction of bone trabeculae in implant biomechanics. J Oral Rehabil. 1999;26:640-3.

19. Faverani LP, Bar�o VA, Ramalho-Ferreira G, Delben JA, Ferreira MB, Garcia J�nior IR, Assun��o WG. The influence of bone quality on the biomechanical behavior of full-arch implantsupported fixed prostheses. Mater Sci Eng C Mater Biol Appl. 2014;37:164-70.

20. Pessoa RS, Coelho PG, Muraru L, Marcantonio E Jr, Vaz LG, Vander Sloten J, Jaecques SV. Influence of implant design on the biomechanical environment of immediately placed implants: computed tomography-based nonlinear threedimensional finite element analysis. Int J Oral Maxillofac Implants . 2011;26:1279-87.

21. Ferreira MB, Bar�o VA, Delben JA, Faverani LP, Hip�lito AC, Assun��o WG. Non-linear 3D finite element analysis of full-arch implant-supported fixed dentures. Mater Sci Eng C Mater Biol Appl . 2014;38:306-14.

22. Daas M, Dubois G, Bonnet AS, Lipinski P, Rignon-Bret C. A complete finite element model of a mandibular implantretained overdenture with two implants: comparison between rigid and resilient attachment configurations. Med Eng Phys. 2008;30:218-25.

23. Rubo JH, Capello Souza EA. Finite-element analysis of stress on dental implant prosthesis. Clin Implant Dent Relat Res. 2010;12:105-13.

24. Camargo BA, Drummond LG, Ozkomur A, Villarinho EA, Rockenbach MIB, Teixeira ER, Shinkai RS. Implant inclination and cantilever length are not associated with bone loss in fixed complete dentures: a prospective study. Int J Prosthodont . 2019;32:17-9.

25. Krennmair S, Weinlander M, Malek M, Forstner T, Krennmair G, Stimmelmayr M. Mandibular full-arch fixed prostheses supported on 4 implants with either axial or tilted distal implants: A 3-year prospective study. Clin Implant Dent Relat Res. 2016;18:1119-33.

26. Chrcanovic BR, Albrektsson T, Wennenberg A. Tilted versus axially placed dental implants: A meta-analysis. J Dent. 2015;43:149-70.

27. Lin WS, Eckert SE. Clinical performance of intentionally tilted implants versus axially positioned implants: A systematic review. Clin Oral Implants Res . 2018;29 Suppl 16:78-105.

28. Bevilacqua M, Tealdo T, Pera F, Menini M, Mossolov A, Drago C, Pera P. Three-dimensional finite element analysis of load transmission using different implant inclinations and cantilever lengths. Int J Prosthodont . 2008;21:539-42.

29. Omori Y, Lang NP, Botticelli D, Papageorgiou SN, Baba S. Biological and mechanical complications of angulated abutments connected to fixed dental prostheses: A systematic review with meta-analysis. J Oral Rehabil . 2020 Jan;47:101-11.

30. Fazi G, Tellini S, Vangi D, Branchi R. Three-dimensional finite element analysis of different implant configurations for a mandibular fixed prosthesis. Int J Oral Maxillofac Implants . 2011;26:752-9.

31. Daudt Polido W, Aghaloo T, Emmett TW, Taylor TD, Morton D. Number of implants placed for complete-arch fixed prostheses: A systematic review and meta-analysis. Clin Oral Implants Res . 2018;29 Suppl 16:154-83.

32. Lima LB, de Freitas NR, Novais VR, Simamoto J�nior PC. Impact of implant number on mandibular implantsupported profile prostheses: a systematic review. Int J Oral Maxillofac Implants . 2018;33:795-807.

33. de Luna Gomes JM, Lemos CAA, Santiago Junior JF, de Moraes SLD, Goiato MC, Pellizzer EP. Optimal number of implants for complete-arch implant-supported prostheses with a follow-up of at least 5 years: A systematic review and meta-analysis. J Prosthet Dent. 2019;121:766-774.e3.

34. Ferreira JJR, Oliveira JM, Castellanos SD, Correia A, Reis AR. Design and validation of a short-implant rehabilitation mode. Rev Port Estomatol Med Dent Cir Maxilofac. 2017;58:79-90.

�

Tom�s Geremia

E-mail address: tgeremia@pucrs.br

�

Acknowledgments

Thomas Geremia and Leonardo H. Barcellos contributed equally to the study and should be jointly considered the first author. This study was financed in part by the Brazilian Ministry of Education/Coordena��o de Aperfei�oamento de Pessoal de Nivel Superior - Brasil (CAPES) - Finance Code 001. The authors do not have any conflict of interest related to this study.

�

Ethical disclosures

Protection of human and animal subjects. The authors declare that no experiments were performed on humans or animals for this study.

Confidentiality of data. The authors declare that no patient data appear in this article.

Right to privacy and informed consent. The authors declare that no patient data appear in this article.

�

Conflict of interest

Os autores declaram n�o haver conflito de interesses.

�

1646-2890/� 2021 Sociedade Portuguesa de Estomatologia e Medicina Dent�ria. Published by SPEMD.

This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/).